When the most probable causes have been identified, they are written in the box along with the original effect.ĭe:Ursache-Wirkungs-Diagramm es:Diagrama de Ishikawa fr:Diagramme de causes et effets pt:Diagrama de Ishikawa This page uses Creative Commons Licensed content from Wikipedia ( view authors). Off each of the large bones there may be smaller bones highlighting more specific aspects of a certain cause. These are drawn towards the left hand corners of the paper, and they are each labeled with the causes to be investigated. Cause & Effect DiagramThe cause & effect diagram is the brainchild of Kaoru Ishikawa, whopioneered quality management processes in the Kawasaki shipyards. Cause-and-effect diagram (also called Ishikawa or fishbone chart): Identifies many possible causes for an effect or problem and sorts ideas into useful. The main body of the diagram is a horizontal line from which stem the general causes, represented as "bones". 15 Keywords: quality control, statistical process control, total quality management, cause-and-effect, fishbone diagram, Although it is open to a. Most Ishikawa diagrams have a box at the right hand side in which is written the effect that is to be examined. People sometimes call Ishikawa diagrams "fishbone diagrams" because of their fish-like appearance. Every factor identified in the diagram was included in the final design.

The main causes included such aspects as "touch" and "braking" with the lesser causes including highly granular factors such as "50/50 weight distribution" and "able to rest elbow on top of driver's door". Mazda Motors famously used a Ishikawa diagram in the development of the Miata sports car, where the required result was "Jinba Ittai" or "Horse and Rider as One".

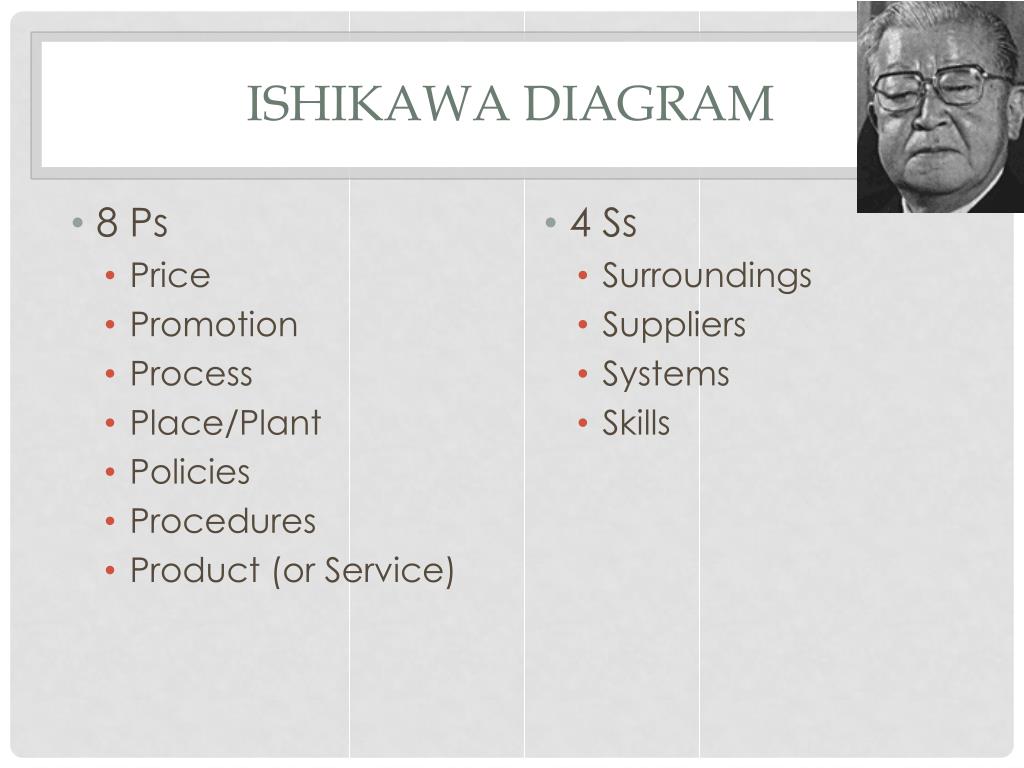

It is also known as a cause and effect diagram.Ī common use of the Ishikawa diagram is in product design, to identify desirable factors leading to an overall effect. Because of its shape, an Ishikawa diagram can be known as a Fishbone Diagram. Control movement with focus on statistical. It was first used by Kaoru Ishikawa in the 1960s, and is considered one of the seven basic tools of quality management, including the histogram, Pareto chart, check sheet, control chart, cause and effect diagram, flowchart, and scatter diagram. Kaoru Ishikawa received many esteemed quality awards including the Deming Prize. An Ishikawa diagram, also known as a Fishbone diagram or cause and effect diagram, is a diagram that shows the causes of a certain event.

0 kommentar(er)

0 kommentar(er)